In chemical, fertilizer, pharmaceutical, and food industries, how to transform fine powder materials into high-strength, uniformly-sized pellets? The roller press granulation production line provides the perfect solution. This system achieves efficient transformation of powdered materials through high-pressure extrusion technology, becoming an indispensable tool in modern industrial production.

Unlike traditional granulation methods, the roller press granulation line adopts unique physical compression principles, producing high-density pellets without needing binders. This “dry granulation” technology not only saves costs but also maintains material purity, making it particularly suitable for pharmaceutical and food industries with strict product purity requirements.

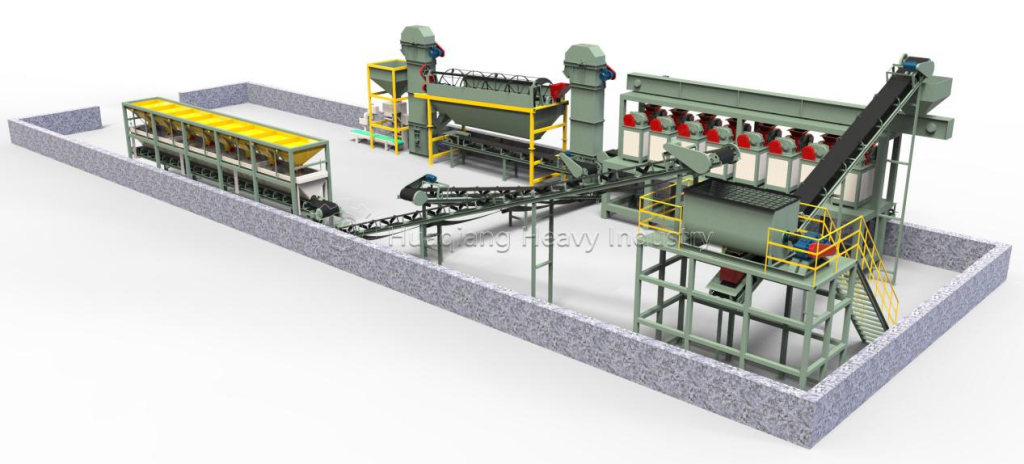

Core Equipment Breakdown

The raw material pretreatment system acts as the production line’s “pre-treatment specialist,” including crushers and screening machines that reduce raw materials to optimal granulation size while removing impurities, laying the foundation for subsequent processes.

The roller press granulator is the heart of the entire system. Through two counter-rotating rollers applying pressure up to tens of tons, it compresses powdered materials into strips or sheets, then converts them into uniform pellets via cutting devices. This high-pressure processing gives the pellets excellent mechanical strength and stability.

Intelligent Production Control

Modern roller press granulation lines are equipped with advanced PLC control systems that precisely monitor and adjust:

- Material ratio – Ensuring consistent composition for each batch

- Extrusion pressure – Automatically adjusted based on material characteristics

- Pellet size – Real-time feedback through screening systems

The post-processing section includes an optional crusher and screening machine. The former handles large lumps generated during extrusion, while the latter acts as a strict “quality inspector,” sieving out oversized or undersized pellets to ensure product consistency.

The fully automatic packaging machine provides the perfect finishing touch, accurately weighing and packaging finished pellets, significantly improving production efficiency while reducing manual intervention.

This production line integrating mechanical engineering with automation technology is revolutionizing powder material processing worldwide, offering industries an efficient, energy-saving, and environmentally friendly granulation solution.