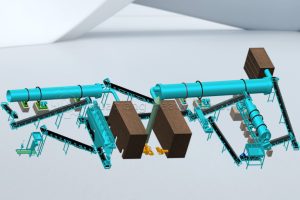

An organic fertilizer production line with an annual output of 10,000 tons includes the following equipment:

Raw material pretreatment equipment: including raw material washing machine, crusher, etc., used to wash and crush raw materials.

Fermentation equipment: Generally, fermentation piles are used for fermentation treatment, and the size and quantity of compost can be designed according to actual conditions.

Solid-liquid separation equipment: Use a solid-liquid separator or filter press to separate the fermentation mixture into solid organic fertilizer and liquid organic fertilizer.

Drying equipment: Use a dryer or air flow dryer to concentrate and dry liquid organic fertilizer to reduce the moisture content.

Crushing equipment: Use a crusher to crush the dried organic fertilizer for subsequent packaging and use.

Packaging equipment: including automatic packaging machines, weighing packaging machines, etc., for automatic packaging of finished organic fertilizers.

Control system: including PLC control system, touch screen operation interface, etc., for automatic control and monitoring of the production line.

In addition, related auxiliary equipment such as conveying equipment, storage equipment, deodorization equipment, etc., as well as corresponding process flow and pipeline layout need to be considered.

When we build an organic fertilizer production line with an annual output of 10,000 tons, we need to choose the appropriate equipment configuration and brand according to actual needs. We can choose a reliable organic fertilizer equipment manufacturer and understand local environmental protection requirements to ensure smooth fertilizer production.