In the development of green agriculture, bio-organic fertilizer, rich in probiotics and capable of improving soil quality, has become a new choice for growers. A bio-organic fertilizer production line, like a “magic factory,” transforms waste materials such as livestock and poultry manure, straw, and food waste into high-quality fertilizer that nourishes crops through the coordinated operation of multiple devices, effectively transforming waste into treasure.

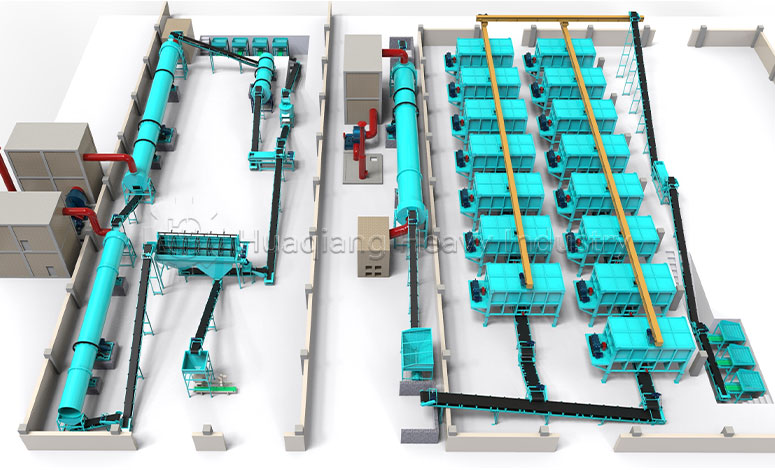

The first step in the bio-organic fertilizer production line is raw material pretreatment. The waste is first fed into a half-wet material crusher, which breaks down large pieces into fine particles. This facilitates subsequent fermentation and allows probiotics to more easily attach. Next, a vibration screener machine removes impurities (such as stones and plastic) and grades the material by particle size to ensure uniform fermentation. If the raw material is too moist, dry straw is added through a horizontal mixer to adjust the moisture content, creating a suitable fermentation environment for the probiotics.

The core process is biological fermentation. Pretreated raw materials are transported to fermentation tanks (or open-air fermentation sites), where specialized probiotic strains are added. During this process, a crawler-type compost turner regularly penetrates the pile, moving oxygen-deficient material from the bottom to the surface, ensuring sufficient oxygen for the rapid growth of probiotics. During the fermentation process, the pile temperature rises to 60-70°C, killing insect eggs and pathogens while promoting the decomposition of organic matter. Composting is complete in approximately 15-20 days.

After fermentation is complete, the finished product enters the “finished product processing” stage. The decomposed material is first crushed again in a semi-wet material grinder to refine its texture. It is then fed into a disc granulator, where it is rolled into granules with a diameter of 2-5 mm for easy storage and application. The granules are then dried in a drum dryer to remove excess moisture. After cooling in a cooler, they are screened by a finished product screening machine to select qualified granules, while unqualified ones are returned for reprocessing. Finally, an automatic packaging machine accurately measures the finished product into 20 kg or 40 kg bags for delivery to the warehouse.

Throughout the entire production line, the central control system monitors all equipment parameters to ensure that indicators such as fermentation temperature and particle size meet the standards. This production line not only solves the problem of waste pollution, but also produces green and environmentally friendly fertilizers.