In the field of modern material handling, loader feeding hopper are revolutionizing the traditional methods of transporting and storing bulk materials through innovative modular design. By cleverly integrating storage, loading, transportation, and unloading functions, this equipment significantly improves material handling efficiency while reducing operational costs.

Innovative Design Concept and Structure

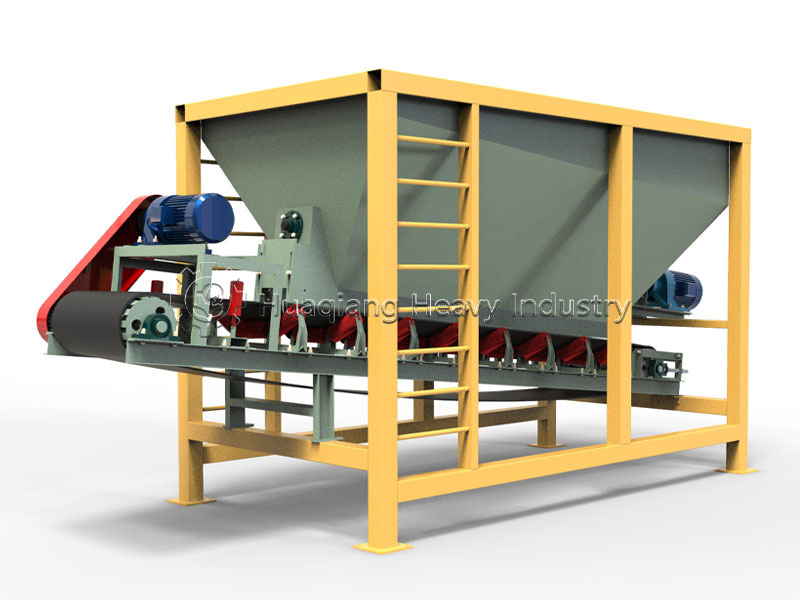

loader feeding hopper adopt modular design principles, primarily consisting of core components such as the silo body, connection devices, discharge systems, reinforcement structures, and safety devices. The silo body is manufactured using high-quality metal materials with smooth inner walls and optional wear-resistant coatings to ensure smooth material flow. The ingeniously designed connection devices enable quick coupling with various forklifts, greatly enhancing equipment flexibility.

The discharge system design deserves special mention. Depending on different operational requirements, material bins can be equipped with manually or hydraulically controlled discharge doors to precisely control material outflow speed and volume. For special application scenarios, conveyor systems can be optionally configured to achieve more uniform and precise material distribution. These design features enable loader feeding hopper to adapt to diverse needs from construction sites to agricultural production.

Efficient Workflow Process

The workflow design of loader feeding hopper is concise and efficient. First, the material bin is secured to the forklift using quick-connect devices, then the forklift’s hydraulic system controls material loading. After loading completion, the forklift transports the fully loaded material bin to the target location, where material is precisely discharged to designated spots through the unloading system. The entire process requires only one operator, significantly reducing labor demands.

This integrated workflow not only improves operational efficiency but also reduces material loss during transportation. The sealed bin design effectively prevents material spillage and dust generation, particularly suitable for materials like fertilizers and grains that require cleanliness maintenance.

Wide Range of Application Fields

loader feeding hopper have extensive application scope. In the construction industry, they efficiently transport building materials like sand and cement; in agricultural production, they are suitable for handling fertilizers, grains, and feed; in warehousing and logistics, they can be used for temporary storage and intra-warehouse transportation of bulk materials; they also play important roles in mining and chemical industries.

The equipment’s strong adaptability is key to its widespread application. By selecting different materials and configurations, loader feeding hopper can meet various special requirements. For example, stainless steel materials can be chosen for corrosive materials, while sealing covers can be added for moisture-sensitive materials. This flexibility makes loader feeding hopper ideal choices across various industries.

Maintenance and Selection Points

Proper maintenance is crucial for extending equipment service life. Daily maintenance primarily includes cleaning the bin, lubricating transmission components, and inspecting safety devices. Regular checks of connection devices and discharge system conditions can help identify and eliminate potential faults promptly.

When selecting equipment, multiple factors need consideration: bin capacity should match forklift load capacity, material selection should be based on material characteristics, and discharge methods should be determined according to operational frequency and precision requirements. Additionally, special requirements of the operational environment must be considered, such as stronger anti-rust capabilities for outdoor operations.

Future Development Prospects

With continuous development of material handling technology, loader feeding hopper will continue advancing toward greater intelligence and efficiency. Applications of new materials will further improve equipment durability and adaptability, while introduction of intelligent control systems will make operations simpler and more precise.

In today’s pursuit of efficient production and sustainable development, loader feeding hopper, with their multifunctional and high-efficiency characteristics, are becoming important components of modern material handling systems. Through continuous innovation and improvement, this technology will provide more efficient and economical solutions for global material handling across various industries, promoting continuous improvement in production efficiency and resource utilization rates.

Efficient Material Flow in Modern Fertilizer Manufacturing

Efficient material handling systems, such as loader feeding hoppers, are vital for connecting the various stages of modern fertilizer production. In a complete npk fertilizer production line, raw materials must be precisely transported to equipment like the npk blending machine for formulation. Similarly, in an organic fertilizer production line, prepared compost from a windrow composting machine needs to be moved to the granulation stage. This seamless logistics support is a key aspect of professional fertilizer manufacturing equipment integration.

The heart of production is fertilizer granulation technology, encompassing various fertilizer granulation processes. The blended material is then shaped by specialized granulators. Equipment choices vary: a disc granulator for shaping spherical pellets is central to a disc granulation production line, while a double roller press granulator forms the core of a dry roller press granulator production line. For specialized products like a bio organic fertilizer production line, the process includes additional microbial treatment. This integration of efficient bulk handling with precise, advanced granulation equipment—from disc granulator machine systems to roller presses—ensures a smooth, continuous workflow for producing high-quality fertilizers at scale.