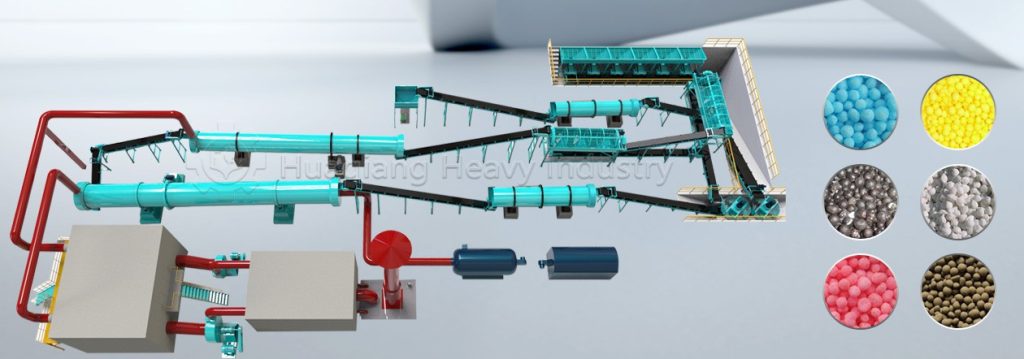

In the sophisticated arena of modern agriculture, the NPK compound fertilizer production line acts like a precise nutritionist, scientifically blending the three core elements of NPK necessary for crop growth. This highly automated production line not only integrates a variety of fertilizer equipment but also represents the perfect marriage of agricultural technology and the laws of nature.

Raw Material Processing: The Starting Point of Precise Proportions

The production line begins with the precise measurement and blending of raw materials. Urea, ammonium phosphate, potassium chloride, and other basic raw materials are fed into the fertilizer crushing system according to the formulated ratio using precision electronic scales. A high-speed pulverizer refines the raw materials to the ideal particle size, ensuring uniformity and completeness in subsequent reactions. Dust removal devices operate simultaneously to maintain a clean production environment.

Mixing and Granulation: A Perfect Fusion of Nutrients

This is the core technical step of the production line. Powdered raw materials enter the twin-shaft mixer for thorough mixing before being fed into the granulation system. In a rotary drum granulator or disc granulator, the materials are agglomerated into granules using an appropriate amount of steam and a binder. This process requires precise control of humidity, temperature, and rotation speed to ensure that the granules meet specified uniformity and strength.

Drying and Cooling: Key to Consistent Quality

Wet granules immediately enter the fertilizer drying system, where they are fully exposed to hot air in the rotary dryer to reduce moisture content. The granules then enter the fertilizer cooler, where they are cooled to room temperature by ambient air to prevent clumping and nutrient degradation. An intelligent temperature control system ensures stable temperature throughout the entire process, protecting heat-sensitive components in the fertilizer.

Screening and Coating: The Art of Finishing

After cooling, the granules are graded through multiple layers of vibrating screens. Qualified products enter the coating process, while oversized or undersized particles are returned for re-granulation. In the coating machine, an anti-caking agent is evenly sprayed on the granule surface, forming a protective film that significantly improves the product’s flowability and storage stability.