In modern agricultural production, NPK compound fertilizers are widely popular due to their balanced ratio of nitrogen (N), phosphorus (P), and potassium (K). To facilitate storage, transportation, and application, fertilizer powders must be converted into granules through a granulation process. The key equipment in this process is the fertilizer granulator, which directly affects the strength, uniformity, and production efficiency of the fertilizer granules.The fertilizer granulators commonly used in npk fertilizer production lines include disc granulator, rotary drum granulator and double roller press granulator.

- Raw Material Pretreatment

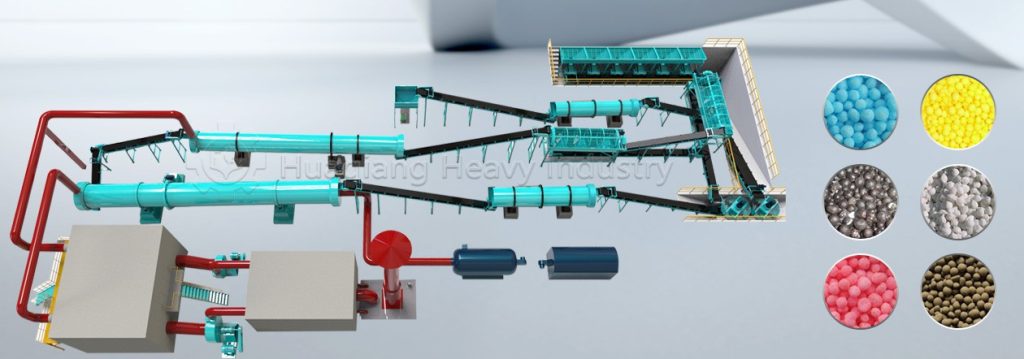

Fertilizer powders (such as urea, ammonium phosphate, and potassium chloride) must first be mixed and moisture-controlled. A blender is used to evenly mix the raw materials according to the formula. An appropriate amount of water or binder is added to increase the powder’s viscosity, creating a foundation for granulation.

- Working Principle of a Granulator

A granulator converts powder into granules through physical or chemical processes.

Rotary drum Granulator: Mixed materials enter a rotating drum where they roll and agglomerate under the action of centrifugal force and a binder, gradually forming spherical granules.

Disc granulator: The tilted rotating disc causes the powder to continuously roll and adhere, forming uniform granules. Particle size can be controlled by adjusting the disc’s tilt angle and rotation speed.

Double roller press granulator: High pressure forces powder through a die to form spherical granules. This granulator is suitable for low-moisture materials and produces high granule density.

- Post-processing of fertilizer granules

After granulation, if the moisture content of the fertilizer granules is high, a fertilizer dryer and a fertilizer cooler are required to control the moisture content. Once the moisture content of the fertilizer granules reaches the standard, the granules are screened and coated.

The NPK fertilizer granulation process, from fertilizer powder to granules, combines physical chemistry with mechanical engineering. Efficient fertilizer granulators not only increase the commercial value of fertilizers but also provide reliable support for large-scale agriculture.