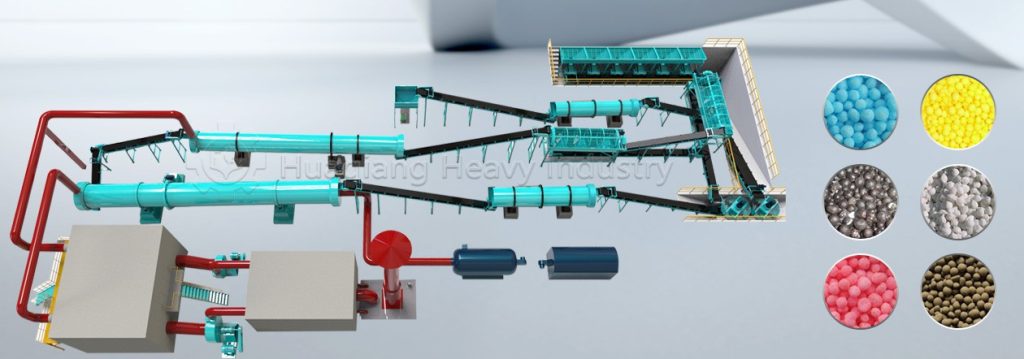

Raw Material Proportioning: The Starting Point of Scientific Formula

Entering the modern NPK fertilizer production line, the first thing you’ll notice is the automated raw material dosing system. Three massive silos store nitrogen (N), phosphorus (P), and potassium (K), three essential raw materials – like three distinct nutrition experts. Electronic batching scales weigh the various ingredients with an astonishing accuracy of ±0.5%. The PLC control system, like a meticulous pharmacist, ensures that each element is precisely proportioned to meet crop needs.

Mixing and Granulation: Creating Perfect Fertilizer Granules

The mixing process is the core of the entire production line. A twin-shaft paddle mixer, operating at 35 revolutions per minute, homogenizes the raw materials in just 90 seconds. The materials then enter the rotary drum granulator. This 3-meter-diameter drum uses steam conditioning and rotation to transform the powdered material into uniform granules of 2-4 mm.

Fertilizer drying and Screening: Key to Quality Control

Fertilizer granules fresh from the fertilizer granulator still contain 8%-10% moisture and require drying. A three-layer rotary dryer uses 120°C hot air to reduce the moisture content to below 1.5% within 20 minutes. A specially designed hot air circulation system reduces energy consumption by 30%. The dried fertilizer granules then pass through a multi-layer vibrating screen. Unqualified granules are automatically sent back for re-granulation. Only high-quality granules with a uniform particle size are packaged.

Intelligent Packaging: The Perfect Finish of the Production Line

In the packaging workshop, fully automatic packaging machines operate at an efficient speed, precisely controlling the weight of each bag of fertilizer.