In the sophisticated world of modern fertilizer production, the NPK production line is like a highly skilled nutritionist, meticulously preparing scientifically balanced “nutritional meals” for crops worldwide. This automated production line combines nitrogen, phosphorus, potassium, and other elements in precise proportions, using a series of intricately coordinated equipment to create specialized fertilizers tailored to the growth needs of different crops.

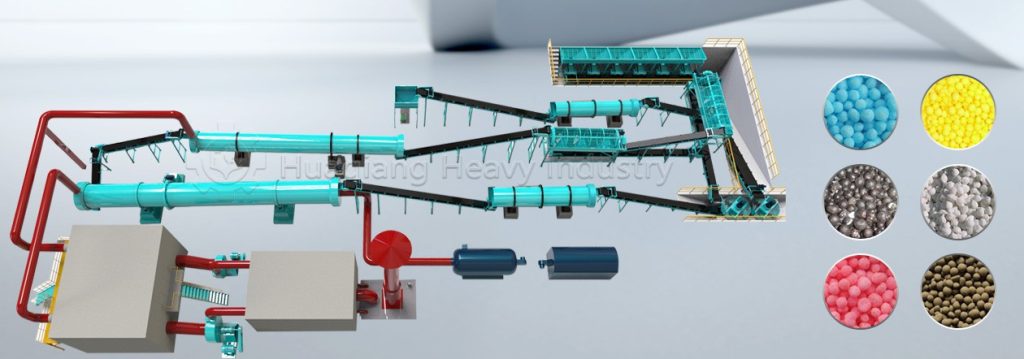

The production journey begins with the precise proportioning of raw materials. Like a meticulous pharmacist, the automated batching system uses high-precision sensors and computer control systems to ensure that each nutrient is precisely weighed according to the recipe. A crusher then refines the raw materials into a uniform powder, preparing them for the granulation process.

The fertilizer granulation process is the artistic heart of the entire production line. Within the rotary drum granulator, the raw materials are gradually agglomerated and formed by the action of a binder, much like a pearl slowly forming within a clam shell. By adjusting equipment parameters, operators can precisely control granule size and density like a tuner, ensuring that each fertilizer pellet achieves optimal physical properties.

During the fertilizer drying process, a rotary dryer uses precise temperature control to remove excess moisture while carefully protecting the active ingredients in the fertilizer. A cooler then lowers the pellet temperature to an optimal level to prevent nutrient loss and clumping. A vibrating screen acts as a rigorous quality inspector, conveying qualified products to the next process while sending unqualified pellets back for recycling.

The coating process provides a protective coating for fertilizer granules. Inside the efficient coating machine, a special coating material evenly envelops each fertilizer particle, like a protective box for precious jewelry, ensuring the stability of nutrients during storage and transportation. This intelligent coating also controls the rate of nutrient release, enabling precise fertilization.

In the final automated packaging step, an intelligent packaging machine completes the metering, bagging, and sealing processes with astonishing precision and speed. Each bag of fertilizer is clearly labeled and includes instructions for use, ensuring farmers use it correctly.

This technologically advanced NPK production line not only demonstrates the ingenuity of modern industrial engineering but also represents a revolution in precision agricultural production.